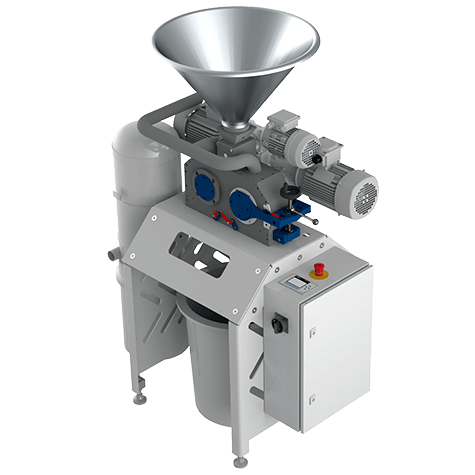

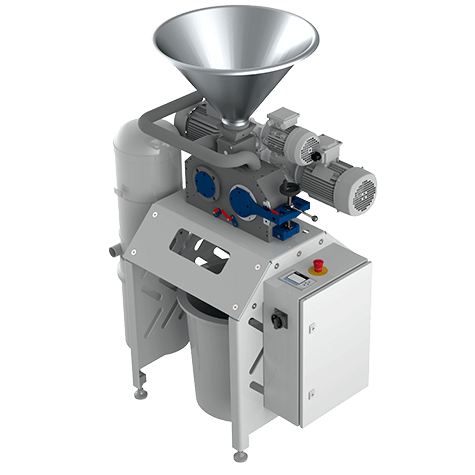

MT 25 – the compact professional mill for small businesses

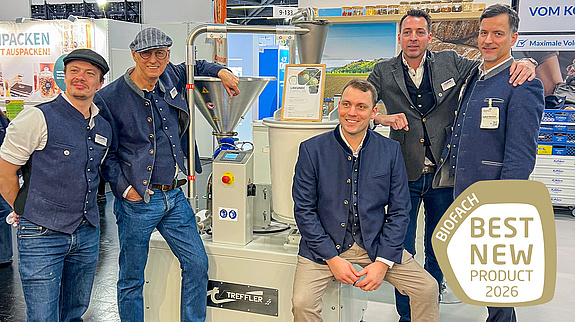

Award-winning: BIOFACH Best New Product Award 2026 – Technology & Equipment category

Now it's finally here: the small Treffler MT 25 mill with a grinding capacity of 20 to 25 kg per hour. Above all, the mill closes one of the gaps in the infrastructure between production and farm technology and the final stage of food production. It makes regional, agricultural and artisanal value creation efficient using state-of-the-art technology.

The right size for farms, bakeries, pasta manufacturers, other food producers and community-supported agriculture (CSA) schemes

With a capacity of around 25 kg/h, the MT 25 is explicitly designed for small and medium-sized businesses and structures: farm processors, community-supported agriculture, small producer cooperatives or bakeries can use it to grind exactly the quantities they need every day – without having to invest in industrial-scale technology.

Technically professional, economical on a small scale

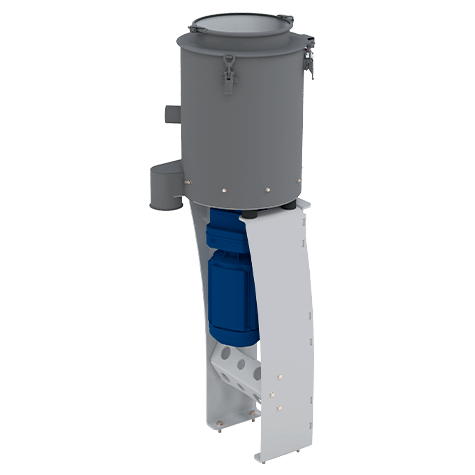

The mill is fully enclosed, low-dust and energy-efficient, with vacuum extraction and sieve replacement – technologies that are otherwise reserved for large commercial mills.

At the same time, the MT 25 is compact and requires little space.

Quality: genuine wholemeal flour from the region

At low grinding temperatures, all grades of flour can be produced from the whole grain – from very fine wholemeal flour to single or double-milled flour.

With the MT 25, whether from 5 kg or 500 kg of grain or legumes (e.g. peas), a 100% flour yield can be achieved – i.e. without any loss.

The ‘maturation process’

It is not necessary to treat the flours (e.g. from wheat or spelt) produced with the Mühlomat. This means that the usual addition of vitamin C (ascorbic acid, E 300) as a processing aid, which is used to achieve ‘artificial flour maturation’, or the otherwise time-consuming but necessary flour maturation through storage, can be dispensed with.

Like its larger counterparts, the MT 25 works with negative pressure and pneumatic conveying: the flour is drawn through the system by an air flow. This brings the flour into immediate contact with plenty of oxygen. Oxygen promotes oxidative processes that shift the redox state in the flour (oxidation of reducing SH groups, formation of additional disulphide bridges in the gluten).

The result: with the Treffler maturing milling process, the grain is ground so finely and evenly and under such a strong influence of oxygen that many of the processes that would otherwise take place over weeks in the flour silo or by means of flour treatment are practically initiated during and immediately after milling. The flour therefore behaves more like ‘matured’ flour in the bakery, even though it is fresh. The effect of this flour maturation:

- better water absorption

- more stable gluten structure, more stable doughs

- improved volume

- the nutrients and flavours of fresh wholemeal are retained.

Leverage for regional value chains

The small, professional mill makes it possible to retain more value on the farm, in the village and in the region, from grain to finished bread. Farms can cooperate directly with food producers in the region and build their own traceable value chain – instead of anonymously feeding their products (grain and legumes) into the industrial collection structure.

In short, the 25 kg Treffler mill is not just ‘another mill’, but an example of medium technology in the best sense of the word: large enough for professional quality and continuous operation, small enough for agricultural, artisanal and regional structures – and thus a practical building block for resilient, regional grain value chains.

It can meet consumers' desire for short value chains, reliability and a high degree of transparency.

The focus areas and unique selling points of agricultural businesses, such as the cultivation of cereals and legumes in mixed crops, regional conservation varieties, special varieties/mixtures or even heterogeneous populations, can be carried through to the bread shelf and communicated. This is because the raw materials can be processed into single-variety, high-quality flours directly on site at the farm or in the bakery – without any loss of quality due to long storage times or long transport distances to large mills. Last but not least, the ‘mature grinding process’ allows for a high degree of flexibility in the production process.

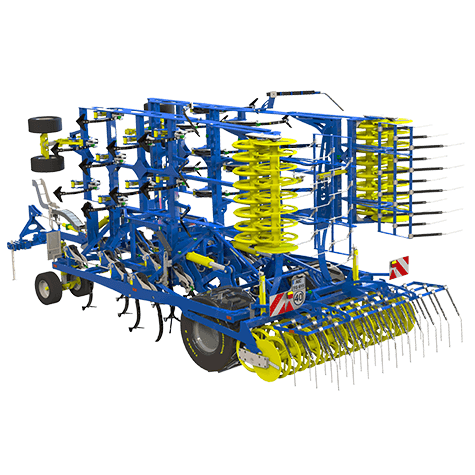

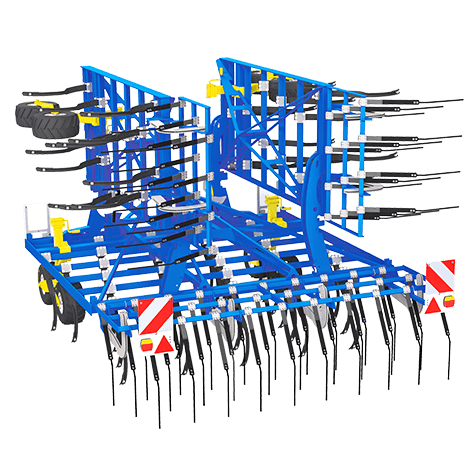

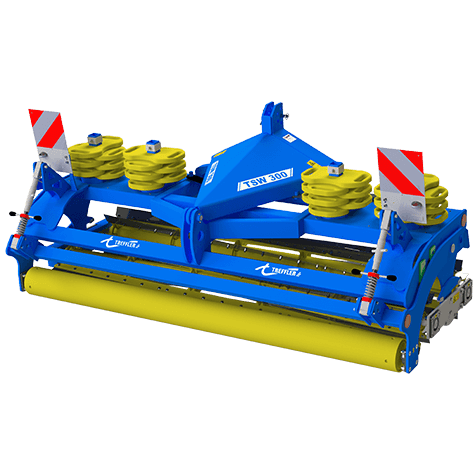

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/user_data/bilder/agrartechnik/produktteaser/treffler-praezisions-zinkenstriegel-5-7-teilig.png)

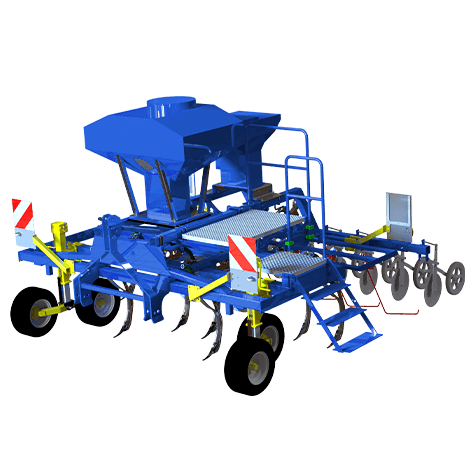

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/user_data/bilder/agrartechnik/produktteaser/treffler-saetechnik.png)