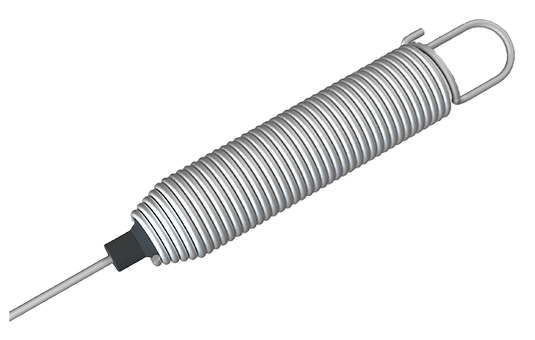

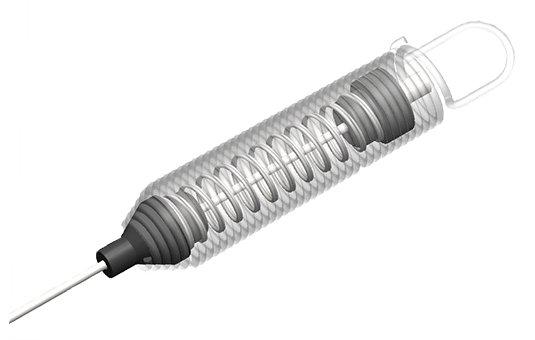

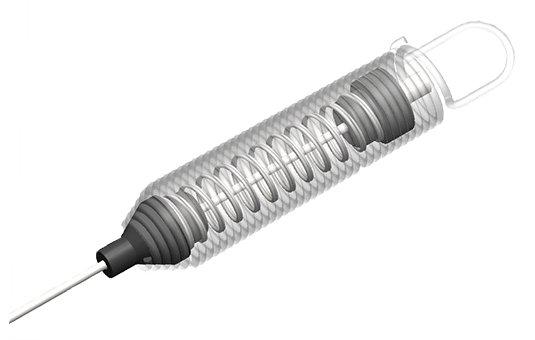

Standard spring

100g and 500–5000g even tine pressure. The standard for working where an even tine pressure between 100 g and 500 g can be dispensed with. The series standard for harrowing cereals and grassland.

Harrows are an effective way of controlling weeds: simply by moving earth during the germination and cotyledon stage of the weeds and employing the power of the sun. A method that works for a broad range of crops, be they small or large. Treffler offers the right type of harrow for every surface and crop.

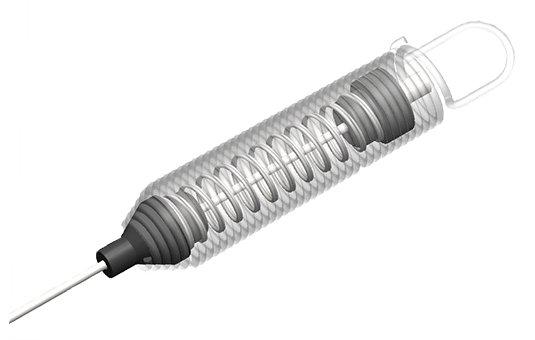

Each tine is mounted so it can rotate in relation to the frame and is connected to a tension spring, which is pre-tensioned for the purposes of adjusting tine pressure. As such, the wire cable is wrapped around a charging shaft and the spring is tensioned.

The unique features of the tine allow it to adapt individually to unevenness in the soil, a characteristic that prevails under all tine pressure settings.

The best result is achieved with an even tine pressure. Our precision tine harrow keeps the preset pressure constant in every tine position – even with potato ridges.

This means you benefit from effective work through precise tine guidance, allowing you to remove weeds laying dorment as early as the germination and cotyledon stage.

0.80 m - 1.30 m (2´7”- 4´3”) | Hand-drawn harrow or 3-pt hitch attachment

1-section version 1.70 m - 3.00 m (5´7”- 9´11”)

3-section version 3.20 m - 9.20 m (10´6”- 30´2”)

5-section version 6.20 - 16.20 m (53´2”- 59´8”) | 7-section version 16.20 - 18.20 m (53´2”- 59´8”)

5-section version 12.20 - 15.20 m (40´- 49´10”) | 7-section version 16.20 - 20.20 m (53´2”- 66´3”)

21.20 - 29.20 m (69´7”- 95´10”)

Springs for even tine pressure. Even in uneven conditions. The spring determines how precisely you can harrow, especially at the early stages. This is where weed control success in the germination and cotyledon stage is at its highest. Work as precisely as the competition as standard. The combi spring works even more carefully with crops, especially in the early stages.

100g and 500–5000g even tine pressure. The standard for working where an even tine pressure between 100 g and 500 g can be dispensed with. The series standard for harrowing cereals and grassland.

100 g to 5000 g even tine pressure. The combi spring is a spring-in-spring system. The internal spring works at a tine pressure of 100–600 g. If a higher tine pressure is selected, only the internal spring operates first. When a tine pressure over 600 g is reached, only the outer tension spring operates. Vital for use in the especially early stages of cultivated plants, particularly corn, soy, sugar beets, ridge crops and special crops.

The ability to adapt the tine pressure to your crops and land is essential for perfect weed control. After all: Using the harrow with maximum weed control is fun and pays off!

Precise maintenance of the working depth – even in fluctuating conditions. The working depth of the tines affects the earth movement and thus the weed control. The optional automatic working depth regulation delivers even results – completely independently.

You need even work quality in harrowing. Only then can you get weeds under control. Stick with the standard tip made from high-quality spring steel for low area output and soils with little crusting. Or go for the optional carbide variant.

Michelin 12.4 R28 AGRIBIB or Michelin CARGOBIB 600/50 R22.5 tyres for driving speeds up to 30 km/h are fitted as standard on chassis harrows. Other tyre sizes on request.

Agricultural lug tread tires leave the soil looser and with less compaction. Running these tires before the harrow allows the tines to more easily bury the weeds. When lug tread tires are used behind the harrow, less surface compaction is created, thus reducing the potential for weeds to germinate.

This pendulum support wheel in a horizontal parallelogram keeps the support wheel flexible between the two ridges. The wheel follows the course of the ridge. As a result, the frame is guided exactly in height and the ridge remains undamaged. Especially useful in imprecise connecting passes.

Your solution for undersowing, resowing and new sowing. Optimum distribution and incorporation of the seeds for your yield. The broad distribution via baffles ensures optimum placement for growth. The precise depth guidance of the tines scatters the fine seeds as needed. Light-dependent germinators in particular are optimally covered with earth.

Control all hydraulic functions with 1 DA control unit. Recommended when attaching the harrow at the front.

Combine the harrow with other equipment. For example, harrow at the front and roll at the back in grassland.

It’s possible to harrow grassland with very good results. The grassland bar successfully levels molehills.

To take the strain off the support wheels in winter, we recommend the use of parking supports, optionally with heavy-duty rollers.

Depending on the application and the crop, individual tines need to be lifted for special crops. Particularly when harrowing at later stages and the fruiting body would be damaged. The harrow then acts like a hoe, just between the rows. This option is rarely used in cultivation.