Wholemeal flours. Whole range.

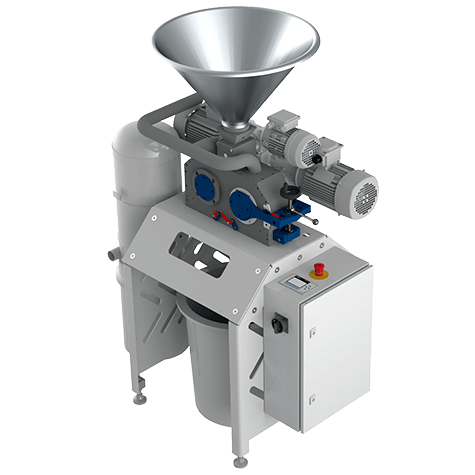

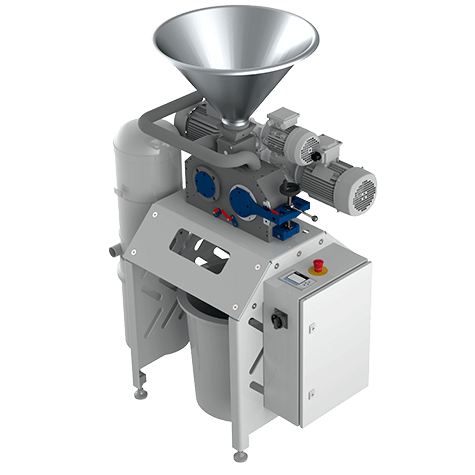

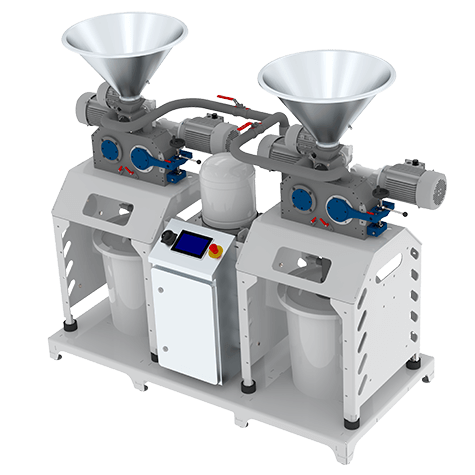

Coarse meal, loose flakes and fine flour: Our insert sieves in the different hole sizes 0.5 mm, 0.75 mm, 1.0 mm, 2.0 mm, 3.0 mm, 4.0 mm and 5.0 mm make everything possible. The grinding speed and direction of rotation can also be adjusted for an optimally balanced ground product. Thanks to its intuitive controls, the Millomat can be operated immediately even without basic knowledge of milling.

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/user_data/bilder/agrartechnik/produktteaser/treffler-praezisions-zinkenstriegel-5-7-teilig.png)

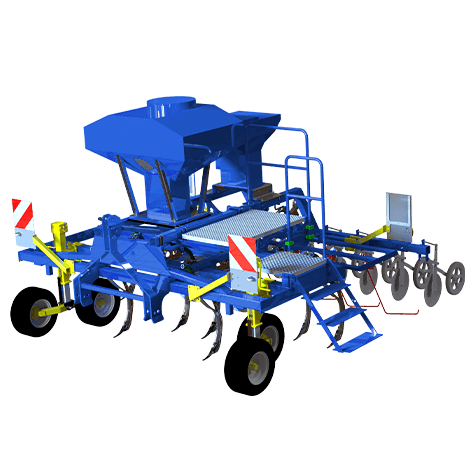

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/user_data/bilder/agrartechnik/produktteaser/treffler-saetechnik.png)